Climate-smart agriculture is an approach, which, among other objectives, helps mitigate greenhouse gas emissions from agricultural production (FAO 2018). Agroforestry systems (AFS) have drawn attention as climate-smart enterprises for temperate and subtropical regions, as they provide high net carbon (C) gains per area, while diversifying operations (Schoeneberger 2009; Schoeneberger et al. 2012). This article focuses on silvopastures (i.e., AFS with trees, forages, and livestock), but many aspects also apply to AFS in general. Estimated C sequestration rates for silvopastures in North America (i.e. trees, roots, and soil) range from approximately 1,600 – 5,400 lb per acre per year (Nair and Nair 2002; Udawatta and Jose 2012). The high degree of variation originates from the complexity of AFS (i.e., soil, climate, species composition, plant density, management, and AFS design). The online-tool COMET-Farm (Carbon Management Evaluation Tool) accounts for these differences, and provides producers the possibility to calculate C sequestration in AFS (Merwin et al. 2009; Ziegler et al. 2016; COMET-Farm 2018). Still, there is limited understanding of the variation in C pools (i.e. where C is stored in AFS and in what fraction) and fluxes (i.e. annual rates of change), especially as AFS mature, which is usually accompanied by reduced C sequestration rates. A comprehensive C budget (i.e. how much carbon enters and leaves the system) helps to understand where C is stored and how these C pools change over time. In general, the important C pools in silvopastures are the soil, trees, and forages. Trees and forages can be subdivided into categories, above- and below-ground biomass. The tree above-ground C pools are wood (twigs, branches, and trunk), leaves, and fruits, and for forages, the living green material and litter. The below-ground biomass is the tree and grass roots, plus associated organisms such as mycorrhizae. Another important C source is organic fertilizer, which introduces C from outside the system. Livestock also contributes to the C budget, through manure inputs and methane emissions.

In this article, we present a comprehensive example of C budget calculation for an 18-year-old pecan silvopasture in Fayetteville, AR in 2016 and 2017. A total of 115 pecan trees were planted in 1999 on 4.6 acres, of which 80 trees are included in the calculation (other trees were weak growing, were harvested, or died). Orchardgrass and big bluestem were planted between tree rows and later grazed by cattle. Poultry litter was applied as organic fertilizer. The C in organic fertilizer, soil (0 – 12 inch), the above-ground tree parts (wood, leaf, and nut yield), and the forages were estimated using standard lab analysis and destructive sampling (Figure 1). The sample data can be used to produce equations, which help to estimate total C stored in the AFS and to predict amount of C stored in upcoming years. The program COMET farm is based on a similar approach, and uses empirical equations to calculate C storage in AFS. These equations were derived from sample data as well, and the more data we can provide, the higher is the accuracy of our calculations.

Figure 1. Pecan tree harvest to estimate above-ground C pools in woody material, leaves, and nuts, in Fayetteville, AR, August 2016.

Figure 1. Pecan tree harvest to estimate above-ground C pools in woody material, leaves, and nuts, in Fayetteville, AR, August 2016.

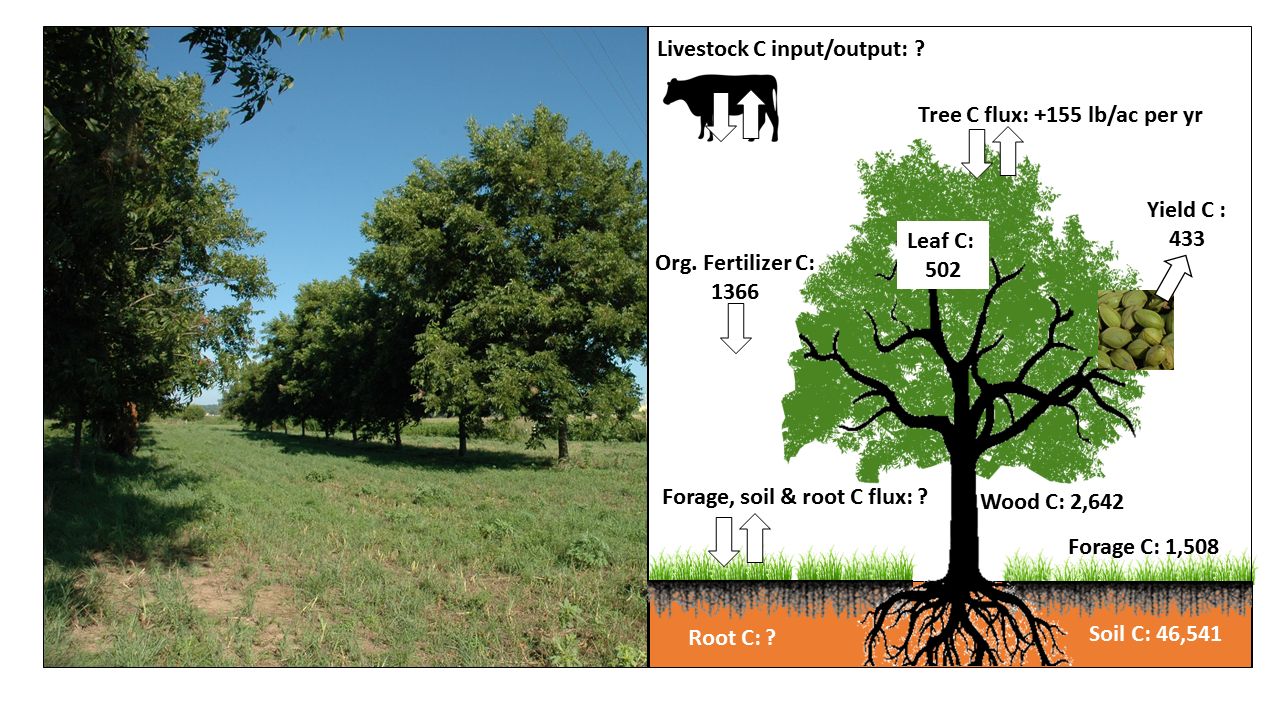

In our example, most C was stored in the soil with 46,541 lb C per acre, followed by tree trunk, twigs, and branches with 2,642 lb C per acre. The soil and wood C make up the bulk of the long-term C storage, because decomposition rates of woody material and organic matter in soils under sustainable management are generally slow. Approximately 433 lb C per acre exits the AFS as nut yield, while 1,366 lb C per acre is applied as organic fertilizer. Tree leaves and forages made up 502 lb C per acre, but is not considered for long-term C storage, because tree leaves are easily decomposed. Forage yield after grazing was 1508 lb C per acre, part of which may contribute to the longer-term C as standing biomass or litter. Forage litter measurements were not included, but can accumulate substantial amounts on the soil surface. For now, we only consider above-ground tree C sequestration in wood (i.e., 2,642 lb C per acre over 17 years) with an estimated rate of +155 lb C per acre and year (Figure 2).

Figure 2. The pecan silvopasture stand in 2016 (left panel), and sketch of the various C compartments of the C budget (right panel).

Figure 2. The pecan silvopasture stand in 2016 (left panel), and sketch of the various C compartments of the C budget (right panel).We still lack information on other C pools and fluxes, such as roots, respiration of soil, forage, and trees, and the inputs and outputs of livestock. This example shows how complex a comprehensive C estimation in AFS can be. It is therefore important to provide easy applicable programs such as COMET farm to allow growers to calculate carbon storage for their AFS.

References

COMET-Farm (2018) Whole farm and ranch online calculation of carbon and greenhouse gas emissions. http://cometfarm.nrel.colostate.edu/

Food and Agriculture Organization (FAO) (2018) Climate-smart agriculture. http://www.fao.org/climate-smart-agriculture/en/

Merwin ML, Easter M, Townsend LR, Vining RC, Johnson GL (2009) Estimating carbon stock change in agroforestry and family forestry practices. Agroforestry Comes of Age: Putting Science into Practice. Proceedings of the 11th North American Agroforestry Conference, Columbia, Missouri, USA, pp 17-24. http://www.centerforagroforestry.org/pubs/proceedings.pdf

Nair PKR, Nair VD (2002) Carbon Storage in North American Agroforestry Systems. In: Kimble J.M. LR, Birdsey R., Heath L.S. (ed) The Potential of U.S. Forest Soils to Sequester Carbon and Mitigate the Greenhouse Effect, CRC Press, pp 333-346

Schoeneberger MM (2009) Agroforestry: working trees for sequestering carbon on agricultural lands. Agroforestry Systems 75: 27-37

Schoeneberger M, Bentrup G, de Gooijer H, Soolanayakanahally R, Sauer T, Brandle J, Zhou X, Current D (2012) Branching out: Agroforestry as a climate change mitigation and adaptation tool for agriculture. Journal of Soil and Water Conservation 67: 128A-136A

Udawatta RP, Jose S (2012) Agroforestry strategies to sequester carbon in temperate North America. Agroforestry Systems 86: 225-242

Ziegler J, Easter M, Swan A, Brandle J, Ballesteros W, Domke G, Chambers A, Eve M, Paustian K (2016) A model for estimating windbreak carbon within COMET-Farm™. Agroforestry Systems 90: 875-887

Written by Dold, C.*1; Thomas, A.L.2; Sauer, T.J.1; Ashworth A. J.3, Philipp, D.4, Adams, T.C.5

* Corresponding author

Email contacts: This email address is being protected from spambots. You need JavaScript enabled to view it., This email address is being protected from spambots. You need JavaScript enabled to view it.; This email address is being protected from spambots. You need JavaScript enabled to view it., This email address is being protected from spambots. You need JavaScript enabled to view it.; This email address is being protected from spambots. You need JavaScript enabled to view it.; This email address is being protected from spambots. You need JavaScript enabled to view it.

1 USDA-ARS, National Laboratory for Agriculture and the Environment, Ames, IA 50011-3120, USA.

2 University of Missouri, Division of Plant Sciences, Southwest Research Center, 14548 Highway H Mt. Vernon, MO 65712, USA.

3 USDA-ARS, Poultry Production and Products Safety Research Unit, University of Arkansas, O-303 Poultry Science Center, Fayetteville, AR 72701, USA.

4 University of Arkansas, Division of Agriculture, Department of Animal Science, Center for Agricultural and Rural Sustainability, 217 Agriculture Building, Fayetteville, AR 72701, USA.

5 University of Arkansas, Division of Agriculture, Department of Poultry Science and The Center of Excellence for Poultry Science, 1260 W Maple, Fayetteville, AR 72701, USA.